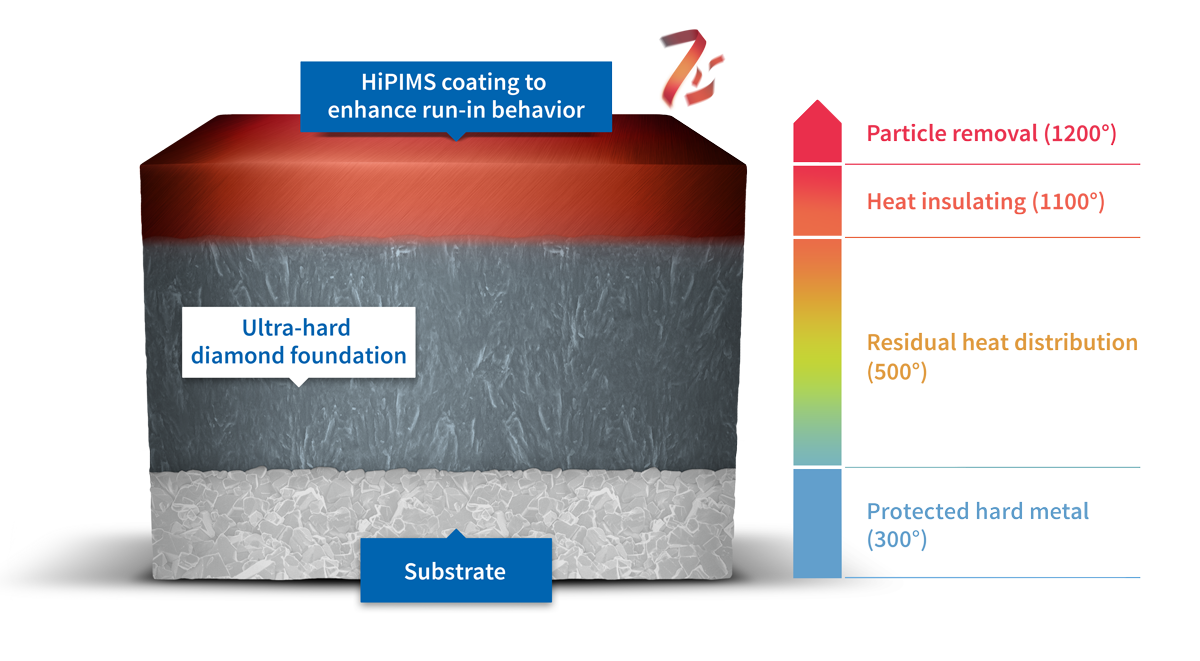

The best of two worlds

HiPIMS ensures that the coating material has heat-insulating properties. The energy is sent to the chips, which reduces cratering wear. Diamond as an ideal heat conductor supports and distributes the heat evenly within the substrate, thereby preventing the carbide from overheating. This results in especially heat-resistant coatings.

With diamond, the hardest of all materials, HiPIMS gets the best possible base. The tool remains stable and there is no “eggshell effect”.

The surface of the new coating materials is softer than pure diamond coatings, which improves the running-in behavior of the tools. Despite this, the tools benefit from the extreme hardness of diamond and deliver optimum productivity.

In the new coating materials, the HiPIMS component provides a conductive surface. This, for instance, makes measuring easier when cutting graphite or circuit boards, which favors automated manufacturing.